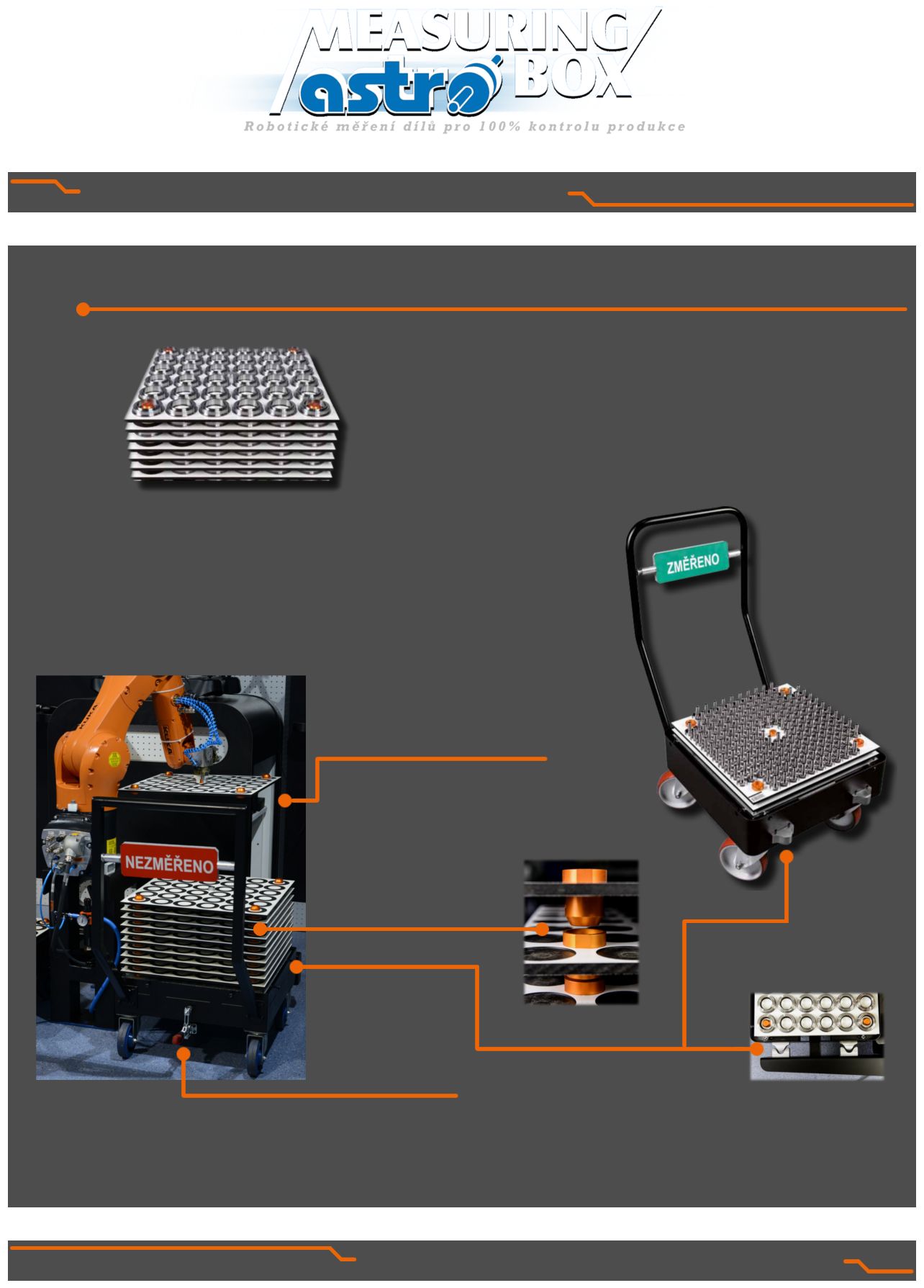

Pallet system

This is a highly effective supplying system for Astrobox ensuring long term unmanned operation of the system. At the beginning there are two trolleys positioned in the box. One carries pallets with individual products to be tested and the other is empty.

First the robotic arm takes the first product from the trolley and moves it on the measuring station. After the requested dimensions are measured and the product is acceptable the arm places it on the second trolley. If the dimensions are off pre-set tolerances the part is placed separately. The application for putting defective parts aside is chosen based on shape and size of tested parts.

Copyright © 2014. Astro kovo plzeņ s.r.o. All Rights Reserved. | www.astro-kovo.cz

High quality construction of the trolley allows it to carry up to

12 pallets.Four Swivel casters, covered in quality and solid rubber, guarantee

good handlingeven when the trolley is full. Each trolley is furnished with two-sided plate with

TESTED/

NOT TESTED sign.

Two precision prisms are used to position the trolley next to the structure. The precision mounts offer identical positions of the trolleys.The trolley also has

a quick hitch lever brake.Each type of measured parts has its own bespoke pallets made from a special material according to shape and size of said parts. We even provide semi-finished pallets in which you can fabricate your own shape. Two-sided pallets also allow reducing the number of pallets used when testing more than one type of product.

after all parts on the pallet are tested the robotic arm moves them

over to the second trolley and

the measurement continues

the location and stability of pallets on the trolley is ensured by precise tapered pins

two precision prisms are used to position the trolley next to the structure

quick hitch lever brake